Cryptocurrency was never intended to be invented. The invention was a digital cash system which is completely decentralized, without a server or central authority similar to a Peer-to-Peer network for file sharing, which led to the emergence of cryptocurrency.

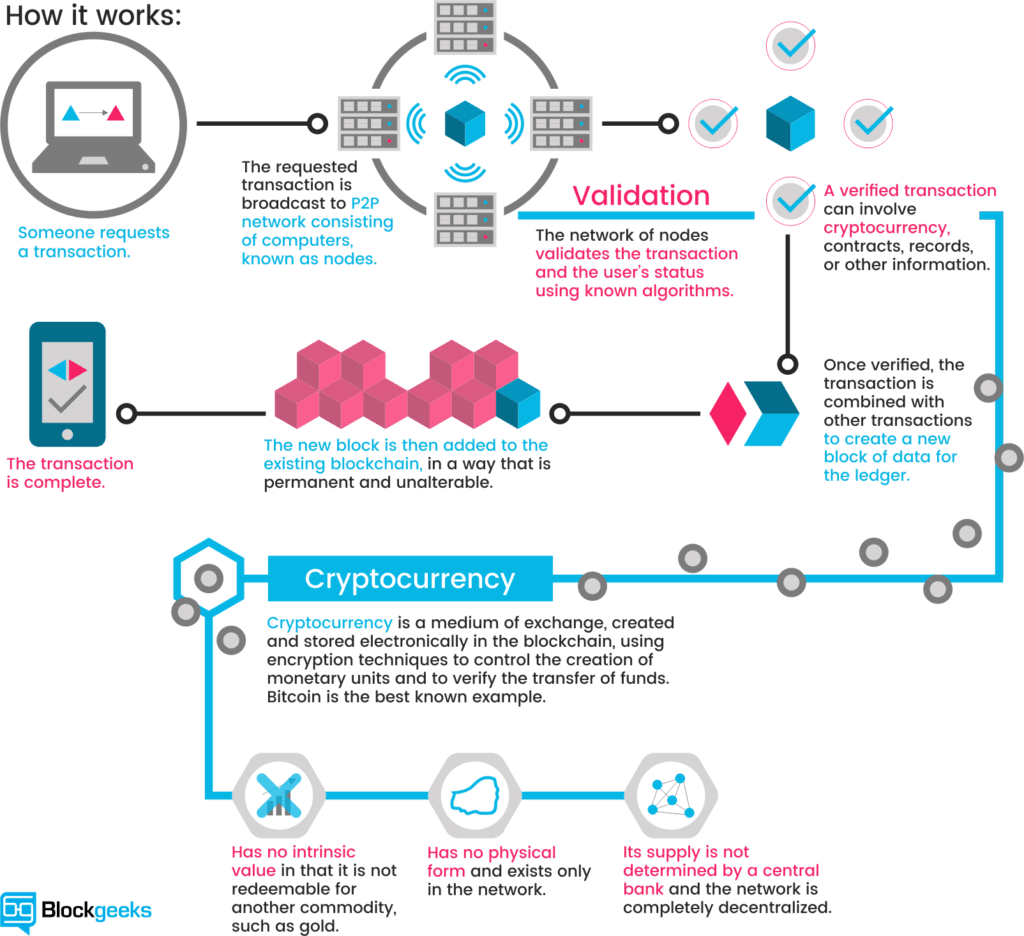

Cryptocurrency can be defined as limited entries in a database no one can change without fulfilling specific conditions. A cryptocurrency has a network of peers which records all transactions. A transaction is complete only when it gets confirmed by miners and it is permanent, forming a part of historical transactions called block chain.

Working of Cryptocurrency

Some of the popular cryptocurrencies are Bitcoin, Ether, Litecoin, Monero, Ripple. Bitcoin is the largest cryptocurrency and often regarded as the first cryptocurrency, even though prior systems existed.

Advantages of Cryptocurrency:

- No central authority, flexibility to make transactions all across the world.

- Almost impossible to manipulate transactions due to the additional layer of security called cryptography.

- All transactions have to be confirmed by miners, and once confirmed they are immutable.

- Personal information is hidden, thereby reducing the possibility of identity theft.

- Minimal processing fees.

Disadvantages

- If the holdings are not backed up, a computer crash can cause loss of cryptocurrency.

- There are constant fluctuations of cryptocurrency value.

http://blockgeeks.com/guides/what-is-cryptocurrency/

http://www.moneycrashers.com/what-are-bitcoins/