ERP Failure: Nike in 2000

In 2000, Nike lost an estimated $100 million due to issues with its ERP implementation. Nike had spent $400 million to upgrade its ERP system for fulfillment of its warehouse orders, but there were issues with the newly installed I2 supply and demand software planning system. This resulted in the output and production of “Air Garnett” sneakers, than were needed. Rather than help increase the efficiency of matching the supply of sneakers with its demand, the new software glitch ended up producing more of the lower demand “Air Garnett” sneakers instead of the incredibly popular and in demand Air Jordan sneakers. The issue was as a result of tying to implement the new I2 software with existing legacy software. This also resulted in a 20% dip in their stock price of Nike at the time.

This failure of Nike in 2000 is key in expressing the importance of properly planning and understanding the business processes for which an ERP system is implanted in. In this case, it applies for companies, like Nike that have very unique supply chain processes, and also need to thoroughly plan these strategies, as being able to predict and properly understand supply and demand planning is crucial because the demand for different shoes and products can shift dramatically based on market requirements and demands.

Sources:

Insights and wisdom from an ERP consultant

Earlier this week, I had the opportunity to sit down (technically, via video conference) with an actual business process consultant and discuss how companies migrate to a new ERP system in the real world. Elisa Bertelli (LinkedIn profile) is a Deloitte consultant based in London, UK, and has several years of experience consulting various companies through their ERP migration.

We started off talking about some of the first tasks she usually does with clients during the beginning of a project. “First we look at all of the business functions, all the business departments – sales, finance, production, human resources. And then we interview them on what their daily tasks are. We try to piece together the operational steps involved in the various tasks that they do. Then once we understand the steps, we can then find where the processes can be improved.” So, say if a tasks usually takes ten steps to complete, the consultant may present a new process that only takes four steps. “Because the main goal is to make the tasks take less time, which saves money and resources for the company.”

“After the mapping, we [then] use industry benchmarks as a comparison of how long a certain process should take. Deloitte, and all consultancies, have a repository on industry leading standards and practices, which we refer to in order to make a recommendation of which ERP system is best suited for the client.”

As far as the types of ERP systems used, “sometimes it mainly depends on the industry of the client. Oracle tends to be suited to financial companies while SAP serves manufacturing quite well.” But interestingly, an enterprise can end up using different software for different functions. “For example, a company may use SAP for the back end, while in their front end use a more flexible system – one that is more of a niche system to handle specialized operational needs.”

When it comes to the common challenges or roadblocks when advising clients on a new ERP system, I had expected something along the lines of accurate information gathering during the interviews. Instead, it’s “resistance to change: many people see change as a threat.” The people who usually performs the every day operational tasks are not the ones who decide to switch to a new system. Plus, many have been doing their jobs for a very long time. “In this case, we bring in our Change Management (a dedicated team that helps people with change) to work with the people and reassure them about the new methods and systems.”

Walmart’s Vendor-Managed Inventory Model

Walmart is the world’s largest and most powerful retailer with the highest sales per square foot, inventory turnover, and operating profit of any discount retailer. It’s safe to say that the inventory management is one of the biggest contributors to the success of the company, and one of the factors of its successful IM is contributed by implementation of the vendor-managed inventory model.

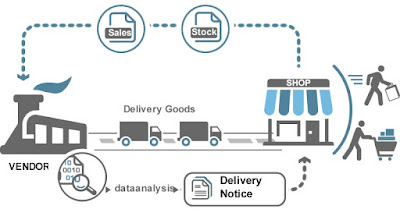

Walmart implements a vendor-managed inventory model in which its suppliers access data, such as current inventory levels and the rate at which certain goods are sold, from Walmart’s information system. Suppliers use this data to decide when to send their goods to Walmart. Then the goods then received from vendor can be owned by the supplier until the customer consumes it (consigned stock) or is owned by the customer when the customer receives (non-consigned stock).

Major Benefits:

As supplier have access to data directly from Walmart’s IM – Reduced delay in movement of Inventory across supply chain.

Reduced cost for inventory management – As financial and human resource expense directly falls on the suppliers saving Walmart a significant cost.

Fig. Vendor Managed Inventory(http://resource.centerscm.org/2015/08/vendor-managed-inventory.html)

(reference: http://panmore.com/walmart-inventory-management

Best Practices for Successful ERP Implementation

Some of the best practices for a perfect implementation of an ERP system are:

1) Executive Backing: getting support and participation from company executives will encourage users to support the process. Moreover, the project can function within the limitations of time, scope and money. It builds overall consensus in the organization, which is critical for a successful implementation.

2)Set Practical Goals: An ERP system is going to solve a lot of problems such as, cost reduction, an increase in productivity etc., but all this is not going to happen in a short period time. Implementation will take time and an ERP system should not be considered as a solution to all organizational problems.

3) Training and Change Management: it is imperative to train the users on how to feel comfortable using an ERP system. If users are confident about the working of the ERP systems, the user adoption will increase dramatically

4) Maintenance Planning: ERP system will have problems and solving those problems will cost money. In order to avoid such situations, it is imperative to foresee and have adequate resources in place to solve problems. This will ensure a long-term success of the ERP implementation.

5) Understanding Key features: Many users don’t have a good understanding of what features the ERP system provides. Knowing the key features and understating them will ensure functions are completed faster, and business objectives are met.

http://www.netsuite.com/portal/resource/articles/erp/erp-implementation.shtml

Tesla: Why Elon Musk ditched ERP vendor SAP to build his own from scratch ?

I want you to think about a situation when you are deciding to wear a suite for a special occasion. You have the option to buy a ready-to-wear suite from a store (Boss for example) with the possibility to customize it a little bit at the tailor so it fits better. The solution is cheap and operational. The other option is buying the material for the tailor so he can tailor your suite from scratch, it will cost you more but will fit you perfectly.

Now think about an analog situation: You are Elon Musk (Tesla’s CEO), the suite is an ERP system, the store is SAP, the tailor is your IT team and the occasion is going to the electrical car market and be a successful and innovative company.

Back in 2012, Elon Musk decision was pretty straightforward, he had his CIO Jay Vijayan ditch ERP vendor SAP and build his own custom ERP from scratch.

The idea came as a solution to deal with one main issue:

Most automakers use vertical ERP systems (for example SAP for car industry). However, this typical solution is an issue for an innovative company like Tesla because their model was different from the typical car makers.

Typically, the industry is working with the dealership model: all sales are required by law in most states to go through franchised dealers. That also includes service, although dealers get reimbursements for warranty-related maintenance and repairs.

Nevertheless, besides the innovative approach of Tesla in making electrical cars, they also wanted to innovate their sales model by maintaining a very direct relationship with its customers since the company has vertically integrated distribution and service.

In this case, coping with a new sales process will affect other processes like procurement and production. For these reasons, the vertical ERP solution was deemed ineffective and constraining for Tesla’s adaptability and ability to move quickly (which is the main competitive advantage that the company has over its larger rivals).

In a 2014 interview with CIO Insight, Vijayan (Tesla’s CIO) commented on the decision to build their own customized ERP:

Elon’s vision is to build a vertically integrated organization where information flow happens seamlessly across departments and where we have a closed feedback loop to our customers. By doing this, we can provide the best possible product, service and overall experience to our customers in the fastest way possible, while also operating efficiently as a business.

Tesla proved that process innovation needs the right tools to support it. The ERP system being a central one, an innovative company should make the strategic and difficult decision of going for a vertical solution with lower customization capabilities or building a laborious highly customized system from scratch. Yes, we are back to the suite dilemma and Elon Musk decision was to wear the tailored suite.

Future of ERP systems

As the changes in the ERP gets bigger adapting to changes like the demands of big data, the growth of the cloud, and the Internet of Things (IOT) are what we are seeing today. Here is a quick look at some of the major trends that will affect ERP in the next few years.

Wider Integration: In theory an ERP system is a complete, self-contained package. In practice more and more companies are discovering that it isn’t. ERP needs to communicate with other software, and systems such as factory floor automation, and vendors and owners are working hard to make that happen.

Already some third-party software is coming equipped with stubs to connect directly with major packages such as SAP and Oracle. Other vendors are providing middleware products that will allow ERP systems to tie to other applications – at the expense of a variable amount of integration effort.

This trend will continue and the integration job will get easier as time goes on a vendors get more sophisticated and users get more aware and demanding.

IOT: With the Internet of Things, the world is becoming a lot more connected and this is going to have a major impact on ERP. More and more devices will be able to communicate over the internet, including sensors and other shop floor devices. This trend will spread down to individual devices on the shop floor, the warehouse and other parts of the business and the information will become increasingly important in maintaining fine control over all aspects of the business.

Ease of Use: Ease of use and ease of installation is an on-going trend. ERP vendors of all classes are hard at work trying to make their products easier. This has been going on for at least the last decade and the trend is accelerating. This is mostly a matter of vendors figuring out how to respond to customers’ demands to simplify the ERP experience.

The Cloud: The cloud, of course, is the most outstanding example of a future trend. While growth of ERP installations in general is in the low single digits, cloud installations are growing at double digits as more users, especially SMEs, find using Software as a Service (SaaS) in the cloud preferable to trying to install a complete system themselves. Since SMEs are the fastest growing segment of the ERP business, this reflects in the overall growth figures for SaaS.

The time frame for all this is variable. The impact of the Internet of Things is probably the furthest off, while the cloud and ease of use are already having an impact today. But over the rest of the decade all of these trends will grow.

Source: http://it.toolbox.com/blogs/inside-erp/the-internet-of-things-and-the-future-of-erp-71508

Top signs that show if a company is ERP ready

Don’t Have Easy Access to Information About Business

Employees across company need immediate access to key data. With an ERP solution, executives can get a holistic view of business operations at any time, while other staff can get the information they need to do their jobs more effectively.

Accounting Takes Longer and Is More Difficult

If it takes ages to reconcile financial information across system an ERP solution can make a significant impact. With all financials in single database, accounting staff won’t have to spend hours in reconciling data manually. They will be more productive, freeing them to deliver critical reports without delays.

Sales and Customer Experience Are Suffering

With an ERP system, staff in every department will have access to the same, up-to-the-minute information. Customer-facing reps should be able to answer customers’ questions without having to hang up the phone and check with another department.

IT Is Too Complex, Time-Consuming

One of the biggest downsides of having multiple systems across a business is that IT management can become nightmare. Maintaining these systems with patches and upgrades can be complex, costly. ERP technology can give agility to respond to changing business needs rapidly.

Reference : http://www.workwisellc.com/5-signs-you-need-erp-software/

Business Intelligence and Big Data work with ERP System

Business leverages Big Data and Business Intelligence with ERP system. This not only accelerates decision-making process but also enacts effective business strategy.

But today, data resides everywhere in manufacturing—in Enterprise Resource Planning (ERP) systems, Product Lifecycle Management (PLM) systems, Manufacturing Execution Systems (MES) and Supplier Relationship Management (SRM) systems, in machine tools and in thousands of spreadsheets, files and folders across the company. Data also resides outside the enterprise, across the value chain with partners on both the supply and the sales sides. The goal is to break down organizational process, data and system silo and automate the collection of data across operations.

For example, collecting data across ERP system and Supplier Management system, cleaning and integrating those data enable business get the real-time insight and make better prediction. Moreover, access to real-time supply chain information helps identify issues before they happen, reduces inventory and potentially reduces capital requirements. Moreover, connecting to suppliers’ information enables location tracking, remote monitoring of inventory and reporting of parts and products as they move through the supply chain. All these information help manager to make decision and conduct business transformation.

Overstock.com’s Failure in ERP Implementation

Overstock.com, is an American online retailer with headquarter in Cottonwood Heights, near Salt Lake City, Utah. It was launched in May 1999, went public in May 2002, and after achieving significant growth and profits in some early quarters, achieved a profit of $7.7 million in 2009.

Before 2003, Overstock was using a home grown ERP package which recorded customer transactions in batches. In 2003, Overstock decided to implement Oracle Virtual Machine ERP to record daily transactions and avail benefits.

Unfortunately, the implementation was a failure. Overstock.com’s customer tracking systems were down for nearly a week. Investors lost money because for five and a half years’ overstock had reported false financials and led the company in 2008 to reduce its revenue over that time period by $12.9 million and a net loss of $10.3 million. The new ERP system also failed to subtract shipping revenue for those cancelled orders. The $2.95 charges per order eventually added up over time and became huge loss.

The short timeline contributed to the lack of research and development of the Oracle ERP system leads to this failure. Due to the rushed schedule, some modules testing was skipped. Besides, the system was not properly tested to identify its shortcoming in handling large amounts of orders. There was inadequate testing and insufficient time to debug the system to ensure its functionality. And there was no contingency planning to deal with changes in the business operations.

The failure of Overstock.com can be used as a lesson for companies who plan to implement an ERP system. First of all, Project scope should be clearly identified with realistic time targets, and all employees should be well-trained in the new software. Secondly, top management and the implementation team should have a close communication with the software vendor, consulting firms and IT people, ensuring that the project progress is running on the right track. Last but not the least, a contingency plan of how to survive in case of system failures should be developed.

![]()

Reference:

Success and Failure Examples of ERP Implementation

http://www.slideshare.net/sunidhikumari1/success-and-failure-examples-of-erp-implementation