Walmart is the world’s largest and most powerful retailer with the highest sales per square foot, inventory turnover, and operating profit of any discount retailer. It’s safe to say that the inventory management is one of the biggest contributors to the success of the company, and one of the factors of its successful IM is contributed by implementation of the vendor-managed inventory model.

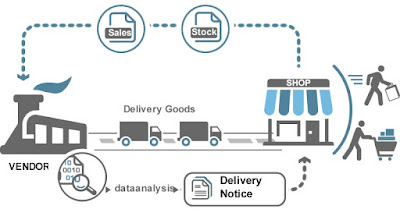

Walmart implements a vendor-managed inventory model in which its suppliers access data, such as current inventory levels and the rate at which certain goods are sold, from Walmart’s information system. Suppliers use this data to decide when to send their goods to Walmart. Then the goods then received from vendor can be owned by the supplier until the customer consumes it (consigned stock) or is owned by the customer when the customer receives (non-consigned stock).

Major Benefits:

As supplier have access to data directly from Walmart’s IM – Reduced delay in movement of Inventory across supply chain.

Reduced cost for inventory management – As financial and human resource expense directly falls on the suppliers saving Walmart a significant cost.

Fig. Vendor Managed Inventory(http://resource.centerscm.org/2015/08/vendor-managed-inventory.html)

(reference: http://panmore.com/walmart-inventory-management